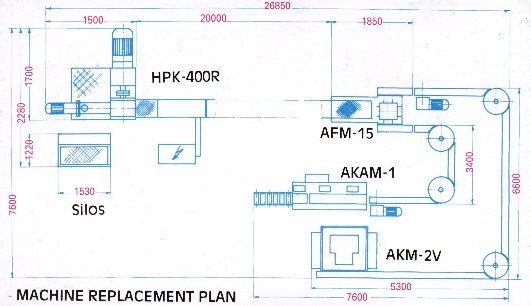

Cube Sugar Machines

General Definition :

Full Automatic HPK-400 R type cube sugar pressing and packaging

machines are self controlling and products of high technology. They are able

to mix the granulated sugar with certain amount of water them in cubic form on to a

stainless belt which goes through drying tunnels and then meets the box belts which

carries boxes to be filled with three layers and cover them automatically.

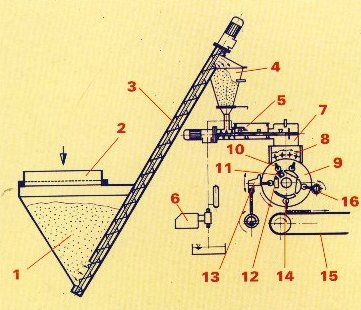

Working Instruction :

Sugar is poured to the feeding hall (1) through a vibrate sieve (2).

Then carried up by a feeding spiraled pipe (3) in to the automatic level controlled

storage (4). Sugar is mixed in the mixer (5) with water which is supplied by the dosing

pomp (6) then transferred to the collector (7). Lightly wet sugar carried by the

synchronous loading box (8). 270 mold pins (10) which are located on the cylinder (9) and

passing over the weight regulator cam (11), are compressed by the pressing cam (12) on the

pressing arm (13) in order to give a cubic form to the wet sugar. The pins leave the cubic

sugar on the steel belt (15) while passing over the pouring cam (14). Formed sugar is

automates and filled in three layers in each boxes. The heads of the mold pins are cleaned

by a hair brush (16).

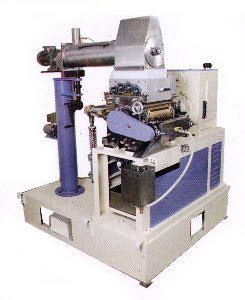

Pressing Head HPK 400 R:

Sugar coming from the feeding hall, goes to the mixer through the

dose section and mixed a certain amount of water which is supplied by the dosing pomp. The

mixture of water + sugar is pushed to the molds from the loading section called

loader-mixer. Sugar goes in to the revolving cylinder mold which pass over the weight

regulator and then compressed cam is poured from beneath of the cylinder in cubic forms on

the belt in lines. Then the heads of the mold pins are cleaned by a hair brush.

Drying Conveyor :

The cubic sugars which are poured on the drying belt in lines are

dried by the heat while going through the 20 meters long drying tunnels. The very special

heat transferring system which was improved and practiced supplies less consumption of

electricity.

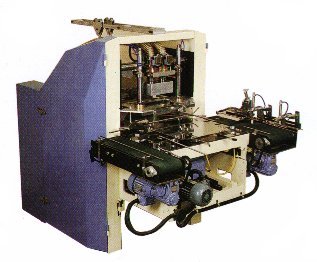

Boxing Machine AKM-2V:

The printed and cut cardboard's are vacuumed in the store section of the

box machine and glued in the mold, are left to the belt in order to be taken to the

filling automate. The daily capacity of the box production machine is 40.000 unit.

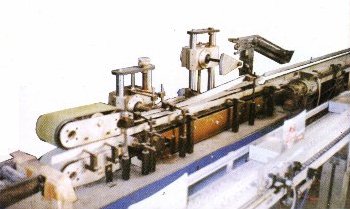

Filling Automate AFM-15 :

The cubic sugars coming out of the drying owens are

carried by belt up to the filling point. At the same time the boxes coming from the box

machine are transferred to the filling point by the rotating tray. The cubic sugars are

put into the boxes in blocks as three layers by the vacuumed filling head then sent to the

cover line.

Covering AKAM-1 :

The boxes which are filled with the cubic sugar by the filling

automate are covered glue pressed and platted at the covering machine.

Technical

Specifications |

| Type |

HPK-400R |

HPK-400 RK |

| Capacity |

12500 kg/day |

18000 kg/day |

| Cubic sugar dimensions |

11 x 16.5 x 14 mm |

18 x 18 x 18 mm |

| Molds in total |

270 unit |

176 unit |

| Head rotation |

12.5 rt |

12.5 rt |

| Dosing pomp |

0-16 lt./hour |

0-32 lt./hour |

| Drying owen length |

20 m |

36 m |

| Main motor |

4 kW 380 V |

5.5 kW 380 V |

| Filling machine |

automatic AFM-15 |

--- |

| Boxing machine |

automatic AKM-2V |

--- |

| Covering machine |

automatic AKAM-1 |

--- |

| Bagging |

--- |

25 kg & 50 kg |

| Electric installation |

60 kW |

80 kW |

Please click here to see the factory view.

For other details please

contact us.

|