Bread Baking

Machines & Equipments

|

|

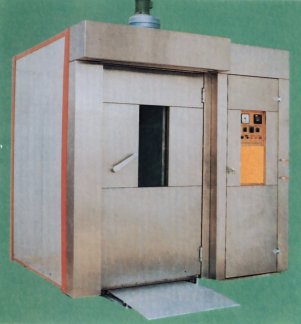

Standard Rotating Oven |

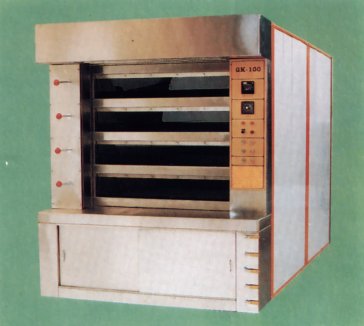

FK 100 Multi - Deck Oven |

Fethil Co. Ltd. manufactures bakery ovens in

three separate sizes and capacities enabling you to get the best results in the baking of

flour products and to have an oven capacity that is in line with your needs.

The heat produced in the oil-fired burner unit (gas-fired models are also

available) is fan-circulated to the baking oven (forced circulation is achieved).

In our ovens which are well designed and made f top quality materials,

high-power steam, economic baking and good heat insulation are all assured.

Our easy and practical feed and discharge systems do not require qualified staff.

Fethil ovens are installed by experienced staff. They have minimum service

requirements, are reliable and durable.

|

FK-100 Fethil has added a new

dimension to its multi-deck ovens. Which have become a classic in their own sphere. This

oven is a must praticulary for our colleagues who produce a variety of flour products. It

has four seperate decks which provide 10 m˛ of baking space and a capacity of 500 loaves

per hour. Its special design makes it superior to its counterparts. There is no need to

leave empty spaces at the back and sides.

|

Standard Rotating Oven |

Standard |

Medium |

Mini |

| Width mm |

2350 |

1950 |

1900 |

| Depth mm |

1950 |

1550 |

1550 |

| Height mm |

2600 |

2350 |

2250 |

| Pan dimensions mm |

740x980 |

600x900 |

590x800 |

| Number of pans |

14-18 |

12-16 |

11-15 |

| Baking area m˛ |

10,5-13,5 |

6,5-8,5 |

5,2-7,2 |

Baking capacity

loaves per hour |

700 |

420 |

320 |

| Baking time minute |

16-18 |

16-18 |

16-18 |

| Baking heat °C |

260 |

260 |

260 |

| Total power cons. KW/h |

4 |

4 |

2 |

| Oil consumpti.(50 Kg .. lt) |

2 |

2 |

2 |

| Insulation mm |

150 |

150 |

150 |

| Weight kg |

3250 |

2500 |

2000 |

| Min. ceiling height mm |

3200 |

3000 |

2800 |

|

FK-100 Multi-Deck

Oven |

| Number of decks |

4 |

| Lenght of deck mm |

2100 |

| Width of deck mm |

1250 |

| Baking area m˛ |

10 |

| Width of oven mm |

1825 |

| Depth mm |

3250 |

| Height mm |

2250 |

| Height between decks mm |

220 |

| Total power consumption KW |

5 |

| Oil consumption (50 Kg..lt) |

2 |

| Baking capacity (loaves/h) |

400 |

| Baking time minute |

16-18 |

| Baking heat şC |

260 |

| Weight Kg |

4500 |

|

|

|

|

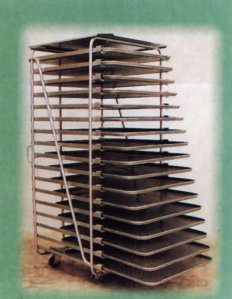

Rotating Oven Pan Carriag |

|

|

| F-HKT Automatic Dough Dividing and Weighning Machine |

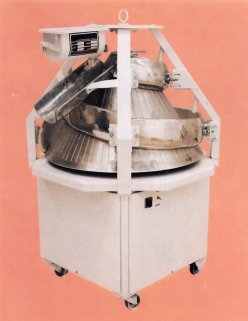

F-KC Conical Rounder |

The autommatic dough diciding and weighing

machine draws the dough from the hopper by means of a vacuum and cuts it by rotation. Thus

the dough is never spoiled or compacted.

Our dough dividing and weighing machine prepares dough potions precut with

the desired sensitivity.

Weight adjustment varies between 150 gr. and 650 gr. capacity adjustment can

be achieved desired from 900 to 2500 loaves per hour. We can also manufacture machines of

different capacities when desired.

The piston bearing and cutting drum are plated with hard chrome, thus

eliminating hazards such as corrosion and wear.

Due to the circulatory lubrication system in our machine, in which alimentary oil

is used, oil consumption is reduced to a minimum. The soundless running and sensitivity of

our machine will be of the best assistance to you in quality bread production. |

Precut and weighed dough is fed into conical

rounder through the inlet duct by means of an aluminium drum. It acquires its rounded

shape as its is rolled smoothly to the outlet duct. From there it passes to the

intermediate proofer. The special channles and the hot air and flour-sprinkling systems

prevent the dough from to the machine. The machine's robust construction, compactness and

soundless running will be of the greatest assistance to you in your bakery.

|

| Width mm |

670 |

| Length mm |

1340 |

| Height mm |

1500 |

| Cuting weight Gr. |

150-650 |

| Capacity Loaves/hour |

900-2500 |

| Motor power |

1,5 Hp, 90 Rev/min |

| Weight Kg. |

515 |

|

| Capacity per hour |

900-2500 |

| Rounding weight Gr. |

300-600 |

| Height mm |

1365 |

| Width mm |

900 |

| Length mm |

1540 |

| Seive agilator motor |

1,5 Hp,900 r/m |

| Heater and air blower |

0,15 Hp, 2800 r/m |

| Heating capacity W |

700 |

| Weight Kg. |

210 |

|

|

|

| F-AD Intermediate Proofer Machine |

F-US Long Roller |

When the dough leaves the conical Rounder it

automatically enters the Intermediate Proofer untouched by hand, falling into the baskets

of the intermediate proofer. The latter has 304 plastic dough baskets. This is no doubling

in this system, which ensures real hygiene and cleanliness. The machine performs a good

intermediate proofing lasting 9-12 minutes.

The position of thedough feed and discharge can be adjusted as desired.

You may also monitor the process inside the machine through the plexiglass panels. |

This machine is used to give a baton shape to

the dough coming out of the intermediate proofer. The dough enters the long roller through

the funnel located on top of the machine and is fed into the rolling-out cylinders of the

long roller where it is rolled into a flat form in two phases. The dough acquires its

baton shape on the left conveyor belt just as if it has been done by hand and the dough on

the belt is thinned at each end by tow seperate pressure boards to the standards required

by the Turkish bakery trade with various adjustements batons in different shapes can be

obtained.

|

| Width mm |

2100 |

| Length mm |

2750 |

| Height mm |

2450 |

| Model |

L |

| Number of baskets |

304 |

| Motor power |

1,5 Hp, 900 Rev/min |

| Profile time minute |

9-12 |

| Weight Kg. |

2000 |

|

| Capacity per hour |

900-2500 |

| Weight of each piece |

300-600 |

| Height mm |

1080 |

| Width mm |

760 |

| Length mm |

2000 |

| Motor power |

1,5 Hp,900 r/m |

| Number of rollers |

4 |

| Weight of conveyor |

470 mm |

| Weight Kg. |

245 |

|

|

|

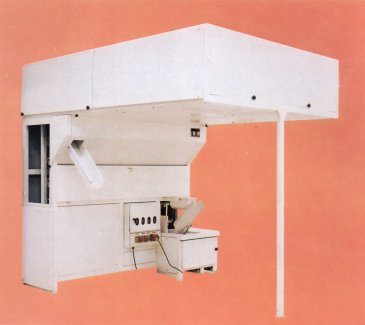

| F-UE Flour Loosening and Sifting |

F-HY Dough Kneading Machine |

Our flour loosening and sifting machine remove

foreign bodies from flour and loosen it. They are mobile and can easily be wheeled to any

part of the dough house. The flour hopper is manufactured in various sizes to contain

between two and ten sacks of flour.

Our sifting machine works soundlessly and is easy to maintain. |

The dough kneading process is realised by the

rotation of the Mixer in the stainless steel bowl. Ýts instigation system is connected

with the shaft coming from the reducer, which is mounted on the body of the machine. It

can knead a full load of dough or a small amount with the same results. It runs quietly

and is extremely durable.

|

| Height mm |

1640 |

| Width mm |

1140 |

| Depth mm |

710 |

| Motor power |

1,5 Hp 1400 Rev/min |

| Weight Kg. |

125 |

| The flour tank (sacks of flour) |

2 |

|

| Interior diameter mm |

1300 |

| Total width mm |

1350 |

| Total Height mm |

1750 |

| Depth mm |

1200 |

| Motor Power |

7,5 Hp |

The flour tank

(sacks of flour) |

8 |

|

For further

information please contact us.

|