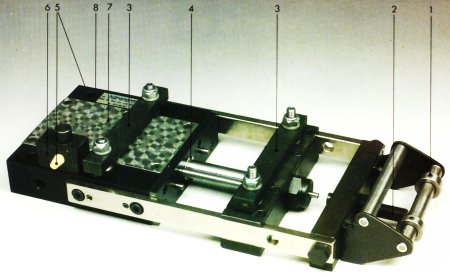

Pneumatic Feeding Units

|

- Quick, simple, silent and sensitive working.

- Compact and useful design.

- All kind of material feeding available. Sheet, iron, steel,

aluminium, copper, plastic etc.

- Easily and quickly install to every kind of machine or tool.

- Up to 151 mm sheet width and 305 mm feeding length.

- Sensitivity ? 0.025 mm.

- High perfonmance and low keeping required.

- 6 Months guarantee.

|

- Adjustable side feed roles assures optimal material flow, complete

compact system.

- Sensitive adjust screw with kontra nut.

- Vise hardness and durable to corroding.

- Piston O-ring, changable.

- Silencers to work silent.

- Command ventil, simple and useful.

- Steel plates to saves body to corroding.

- Feeding speed adjust ventile.

|

|

|

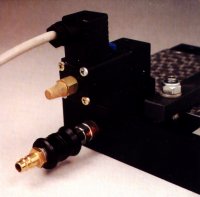

Electro-pneumatic command

ventile

also can be remote control |

Unloading ventile |

Feeder connect with only two

unit screw to mould plate. After one air connection, ready to work. |

- D-Type Pneumatic feeding unit 300x300 mm, Sheet thickness 0.4-0.7 mm

- T-Type Pneumatic feeding unit 300x300 mm, Sheet thickness 0.5 mm, 45

feeding/minute

- T-Type Pneumatic feeding unit 260x260 mm, Sheet thickness 0.5 mm

| Type

|

G1 |

G2 |

G3 |

T2 |

T4 |

T6 |

D2 |

D4 |

D6 |

| Max. material width

(1) |

mm |

51 |

51 |

51 |

101 |

101 |

101 |

152 |

152 |

152 |

| Max. Material

thickness |

mm |

1.20 |

1.10 |

1.00 |

1.80 |

1.70 |

1.70 |

1.80 |

1.70 |

1.60 |

| Feeding length |

mm |

0-51 |

0-102 |

0-152 |

0-102 |

0-203 |

0-305 |

0-102 |

0-203 |

0-305 |

| Feeding unit

(2) |

1/min |

180 |

150 |

120 |

140 |

100 |

60 |

120 |

90 |

60 |

| Feeding power (3) |

N |

180 |

180 |

180 |

210 |

210 |

210 |

400 |

400 |

400 |

| Feeder Clamping

Force (3) |

N |

1050 |

1050 |

1050 |

1050 |

1050 |

1050 |

2200 |

2200 |

2200 |

| Air requirement /

Stroke (4) |

Lt |

0.05 |

0.11 |

0.16 |

0.11 |

0.18 |

0.31 |

0.20 |

0.31 |

0.40 |

| Weight |

Kg. |

3.5 |

4.5 |

7.2 |

8.2 |

11.2 |

13.0 |

11.5 |

16.5 |

22 |

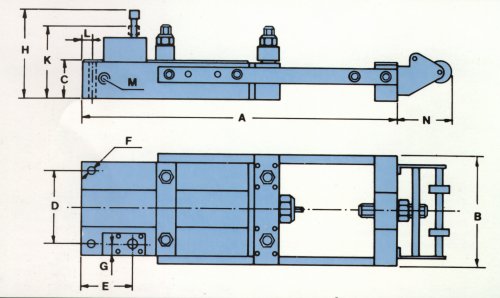

| A |

mm |

295 |

370 |

475 |

372 |

572 |

780 |

390 |

590 |

795 |

| B |

mm |

160 |

160 |

160 |

190 |

190 |

190 |

260 |

260 |

260 |

| C |

mm |

46 |

46 |

46 |

46 |

46 |

46 |

52 |

52 |

52 |

| D |

mm |

108 |

108 |

108 |

138 |

138 |

138 |

190 |

190 |

190 |

| E |

mm |

65 |

65 |

65 |

67 |

67 |

67 |

70 |

70 |

70 |

| F |

mm |

12 |

12 |

12 |

15 |

15 |

15 |

15 |

15 |

15 |

| G |

mm |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

| H |

mm |

118 |

118 |

118 |

118 |

118 |

118 |

124 |

124 |

124 |

| K |

mm |

94 |

94 |

94 |

94 |

94 |

94 |

100 |

100 |

100 |

| L |

mm |

22 |

22 |

22 |

23 |

23 |

23 |

23 |

23 |

23 |

| M |

mm |

1/4" |

1/4" |

1/4" |

1/4" |

1/4" |

1/4" |

1/4" |

1/4" |

1/4" |

| N |

mm |

76 |

76 |

76 |

76 |

76 |

76 |

76 |

76 |

76 |

See also Decoiler Machines

with Moter powered

For further information please

contact us.

|