Plastic

Blow Moulding Machines Double Station Models

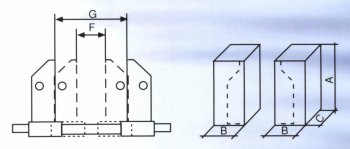

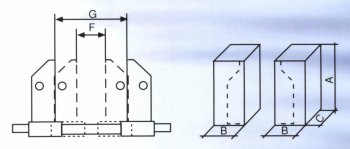

Model SII Double Station

with Deflatcher system

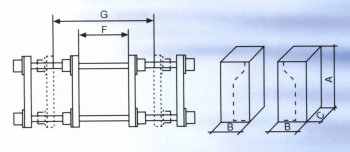

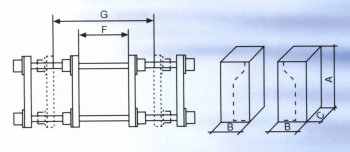

Model XII Double Station

Model |

SII - XII 2000 |

SII - XII 5000 |

SII - XII 10000 |

SII - XII 2000 |

SII - XII 5000 |

| Material |

PE |

PE |

PE |

PVC |

PVC |

| Product Capacity lt |

100 cc - 2 |

2 - 5 |

5 - 10 |

100 cc - 2 |

2 - 5 |

| Clamping Force KN |

40 |

50 |

64 |

40 |

40 |

| Screw Diameter D/L mm |

60/25 |

80/25 |

90/25 |

55/24 |

60/24 |

| Max. Extruder Capacity kg/h

|

45 |

55 |

65 |

30 |

45 |

| Extruder Motor kW |

11 |

15 |

15 |

11 |

15 |

| Heating Zones |

4 |

6 |

6 |

6 |

6 |

| Heating Power kW |

14 |

23 |

26.5 |

13 |

14 |

| Hydraulic Oil Tank Capacity lt

|

210 |

250 |

250 |

210 |

250 |

| Pump Motor kW |

7.5 |

7.5 |

7.5 |

7.5 |

7.5 |

| Max. Hydraulic Oir Pressure BAR

|

100 |

100 |

100 |

100 |

100 |

| Air Pressure BAR |

6 - 8 |

6 - 8 |

6 - 8 |

6 - 8 |

6 - 8 |

| Mould Water Pressure BAR |

4 |

4 |

4 |

4 |

4 |

| Mould Water Temperature oC

|

5 |

5 |

5 |

5 |

5 |

| Max. Water Temperature oC

|

30 |

30 |

30 |

30 |

30 |

| Total Electric Power kW |

32.5 |

45.5 |

49 |

31.5 |

36.5 |

| Model |

G mm |

F mm |

A mm |

B mm |

C mm |

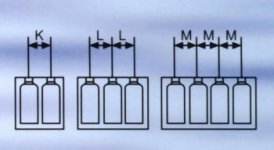

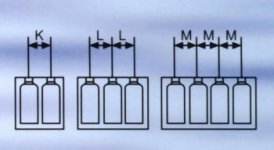

K mm |

L mm |

M mm |

Gross Weight kg |

| SII 2000 |

450 |

180 |

380 |

90 |

320 |

120 |

80 |

60 |

4.500 |

| SII 5000 |

470 |

180 |

400 |

95 |

400 |

160 |

105 |

80 |

5.500 |

| SII 10000 |

570 |

180 |

420 |

110 |

485 |

200 |

135 |

100 |

6.000 |

| Model |

G mm |

F mm |

A mm |

B mm |

C mm |

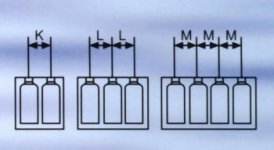

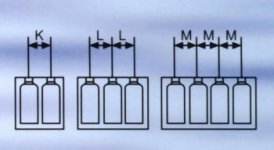

K mm |

L mm |

M mm |

Gross Weight kg |

| XII 2000 |

400 |

100 |

320 (420) |

90 |

230 |

75 |

50 |

- |

3.500 |

| XII 5000 |

580 |

120 |

350 (450) |

95 |

380 |

150 |

100 |

75 |

4.000 |

| XII 10000 |

780 |

150 |

490 |

110 |

420 |

225 |

150 |

110 |

4.500 |

Options :

- Parison Control Unit

- Test Unit

- Automatic Load System

Plastic Blow Moulding Machines

Single Station Models

Model SI Single Station

with Deflatcher System

Model XI Single Station

Model

Model |

SI - XI 2000 |

SI - XI 5000 |

SI - XI 10000 |

SI - XI 2000 |

SI - XI 5000 |

| Material |

PE |

PE |

PE |

PVC |

PVC |

| Product Capacity lt |

100 cc - 2 |

2 - 5 |

5 - 10 |

100 cc - 2 |

2 - 5 |

| Clamping Force KN |

40 |

40 |

50 |

40 |

40 |

| Screw Diameter D/L mm |

60/25 |

70/25 |

80/25 |

55/24 |

60/24 |

| Max. Extruder Capacity kg/h

|

45 |

50 |

55 |

30 |

45 |

| Extruder Motor kW |

7.5 |

11 |

15 |

11 |

15 |

| Heating Zones |

4 |

6 |

6 |

6 |

6 |

| Heating Power kW |

14 |

23 |

26.5 |

13 |

14 |

| Hydraulic Oil Tank Capacity lt

|

210 |

250 |

250 |

210 |

250 |

| Pump Motor kW |

7.5 |

7.5 |

7.5 |

7.5 |

7.5 |

| Max. Hydraulic Oir Pressure BAR

|

100 |

100 |

100 |

100 |

100 |

| Air Pressure BAR |

6 - 8 |

6 - 8 |

6 - 8 |

6 - 8 |

6 - 8 |

| Mould Water Pressure BAR |

4 |

4 |

4 |

4 |

4 |

| Mould Water Temperature oC

|

5 |

5 |

5 |

5 |

5 |

| Max. Water Temperature oC

|

30 |

30 |

30 |

30 |

30 |

| Total Electric Power kW |

29 |

41.5 |

49 |

31.5 |

36.5 |

| Model |

G mm |

F mm |

A mm |

B mm |

C mm |

K mm |

L mm |

M mm |

Gross Weight kg |

| SI 2000 |

450 |

180 |

380 |

90 |

320 |

120 |

80 |

60 |

3.250 |

| SI 5000 |

470 |

180 |

400 |

95 |

400 |

160 |

105 |

80 |

3.500 |

| SI 10000 |

570 |

180 |

420 |

110 |

485 |

200 |

135 |

100 |

3.750 |

| Model |

G mm |

F mm |

A mm |

B mm |

C mm |

K mm |

L mm |

M mm |

Gross Weight kg |

| XI 2000 |

400 |

100 |

320 (420) |

90 |

230 |

75 |

50 |

- |

3.000 |

| XI 5000 |

580 |

120 |

350 (450) |

95 |

380 |

150 |

100 |

75 |

3.250 |

| XI 10000 |

780 |

150 |

490 |

110 |

420 |

225 |

150 |

110 |

3.500 |

Options :

- Parison Control Unit

- Test Unit

- Automatic Load System

For out other Moldes Injection Blow Moulding Machines click here

For other details please contact us.

|