Ironing Press Machines

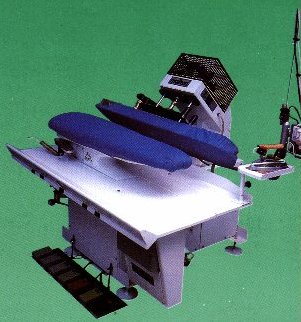

Model UPP 2

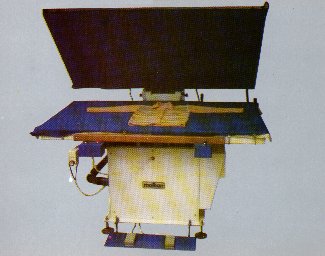

Model UPP-2D4

Electro-Pneumatic Pressing Machine

Under the auspices of electro-pneumatic program, machine does the

pressing itself, automatically. Operator only settles and gets it out. One person can

operate on two machines at the same time. When the first machine starts pressing operator

settle down clothing on the second one and will just push a button to start pressing.

During this time, previous machine will complete its pressing program and will be ready

for settling a new cloth. Thus, manpower, working-time and production cost are saved.

Operator mistakes are prevented, high quality pressing is achieved.

| Technical Specifications |

| Steam Pressure |

3-4 bar |

| Steam inlet |

1/2" |

| Condense outlet |

1/2" |

| Vacuum connection |

2" |

| Air pressure |

6 bar |

| Air inlet |

1/2" |

| Electrical inception |

220/380 V |

Universal Fallback Ironing Press Pneumatic Program

The pressing machine UPP-2D4, covering four features, does the

pressing itself automatically by programming the steaming, vacuuming and close down time.

All controls may also be done manually. For instance; bottom steam and bottom vacuum can

be activated by pushing the treadle. Top steaming and head opening may also be controlled

manually by hand button. Besides pressing the garments, the buck may also be used as a

hand ironing board for the finishing. There is no need a separate hand iron or a board

because of the space provided by the falling down of the head to back of the machine. Thus

the best quality pressing is achieved. All spots can be removed easily by means of a

pistol giving warm air on the cloth laid over the spot removing apparatus, attached to the

pressing machine. Thus manpower and working time are saved. Small sized companies, hotel

laundries and dry cleaning factories prefer this type of press, because of the small place

it requires and the complete ironing set it forms. The pressing machine is practically

operated by MEK20KW type steam generator and PV-1 type vacuum engine in case of non

existent central system.

Other Models

UPP-1 Utility medium size

UPP-2 Utility long-size

UPP-18 Trouser single-leg

UPP-19 Trouser double-leg

UPP-3 , UPP-3A UPP-3B Trouser Top

UPP-25X Utility short-size

UPP-9 Collar

UPP-8 Shoulder

UPP-15 Armhole creasing Dropping and setting

MTYP-2P Stiffening

UPP-10 Forepart off pressing right

UPP-11 Forepart pressing left

UPP-16 Back and side part off pressing right

UPP-17 Back and side part off pressing left

UPP-28 Hindarm and forearm sleeve

KMKP-202P Edge press (left and right)

MTRU-2P Knitwear steaming

UPP-29 Combined seam opening

MPP-1 Ladies skirt

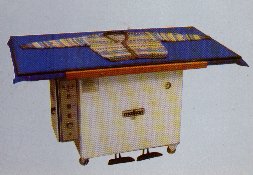

Model UP-21

Model UP-106 D

Ironing Board for Living UP21

- An ideal type of ironing board for the finishing of jacket, coat, overcoat linings.

- Due to strong vacuuming very quick ironing is achieved.

- Using the water pistol for humidifying the lining is an easy way of ironing when the

process is mode with an iron without steam and electricity. It is also possible to iron

the lining by a steam iron, without destroying the fabric.

- This type can be produced in various sizes up to the request, shoulder apparatus may be

added and electric heater with a thermostat or a steam may also be attached.

Retouching Ironing Board UP-106 D

- It is an ideal retouching iron for the ironing of wrinkles left on the fabrics of the

clothes like jackets, during the finishing process.

- When the lapes, shoulder heads an arms are ironed by a hand iron and blowing there will

be no shining and no stain will be left on the lining because of the steam.

- Quick ironing is achieved due to the strong vacuuming. Thus when the clothes are hung

there will not be any deformation.

- Electric heater with a thermostat or steam heater may be used optionally.

| Model |

UP-106 D |

UP-21 |

| Electricity |

380 V |

380 V |

| Motor Power |

0.37 kW |

0.37 kW |

| heating Power |

0.6 kW |

1.5 kW |

| Capacity |

-- |

30 Jackets |

| Machine Size |

117x80x115 cm |

117x80x115 cm |

| Size when packed |

130x90x115 cm |

130x90x115 cm |

| Machine Weight |

65 kg |

70 kg |

| Weight Including Package |

105 kg |

130 kg |

| Standard Apparatus |

- APR-1 Sleeve Buck

- APR-3 Sleeve Buck

- APR-5 Sleeve Buck

- APR-7 Utility Style Buck for count

- APR-9 Double Shoulder Seam Buck

- APR-10 APR-11 Spor Edge Buck Blazer

- APR-12 Kruvaze Edge Buck Small

- APR-14 Utility Style Trousers Leg Buck

- APR-16 Costume Buck Large

|

- APR-2 Shoulder Seam Buck

- APR-4 Utility Style Buck

- APR-6 Combined (edge Buck Small)

- APR-8 Finishing Buck

- APR-9A Shoulder Seam Buck

- APR-13 Utility Style Trousers Leg Buck

- APR-15 Jacket Lining Buck

- APR-17 Costume Buck Medium

- APR-18 Hindarm and Forearm Sleeve

|

Model MTRU-2P

Model MTRU-1

Tricot Ironing Machine With a Cover Pneumatic Central System

MTRU-2P

- Used especially for ironing wool pull-overs.

- Since the below and above covers are heated completely by a steam, the wool pull-overs

become stiff.

- Due to the electro pneumatic system pressure steam, vacuum, staying closed time may all

be regulated by buttons.

- Energy saving is achieved since it is not heated by electricity. The defect risqué are

at minimum level.

- Works with central steam, vacuum, air and 220 Volt electricity.

- Can be produced in various sizes up to request.

Tricot Ironing Machine Independent System MTRU-1

- Used on iron all types of cotton and woll knitted goods.

- The machine produces steam itself by the automatic steam boiler included.

- The same amount of steam is given out on any part of the surface due to the special

system used.

- Vacuum motor set in inside the machine provides a quick ironing by completing the

cooling schock in a short time.

- It can be used as a hand ironing table with a hand iron added optionally.

Tricot Ironing Machine Central System MTRU-3

- Works with central steam and vacuum.

- Works for years without defects up to the lack of electricity connection.

- Can be produced in various sizes up to request.

- Can be used as an ironing table by a hand iron addition.

Type |

MTRU-1 |

MTRU-2P |

MTRU-3 |

| Electricity |

380V |

220 V |

-- |

| Resistance |

12 kW |

-- |

-- |

| Feeding Pump |

0.75 kW |

-- |

-- |

| Vacuum Motor |

0.37 kW |

Central System |

Central System |

| Steam Pressure |

4 bar |

4 bar |

4 bar |

| Air pressure |

-- |

6 bar |

-- |

| Steam inlet and outlet |

1/2" |

1/2" |

1/2" |

| Vacuum Outlet |

150 mm |

2" |

2" |

| Steam Consumption |

25 kg/h |

50 kg/h |

30 kg/h |

| Air Consumption |

-- |

90 kg/h |

-- |

| Capacity |

50 unit/h |

40 unit/h |

50 unit/h |

| Machine size |

185x106x100 cm |

180x185x130 cm |

185x106x100 cm |

| Size of Package |

195x116x120 cm |

190x200x150 cm |

195x116x120 cm |

| Machine Weight |

160 kg |

800 kg |

300 kg |

| Weight Including Package |

220 kg |

950 kg |

400 kg |

For further information please

contact us.

|